Hello friends of the Caesura, welcome back to The Art of Caesura!

Last week, I introduced the topic of 3D printing in kind of an unusual way; I wrote a sort of poetic meditation on the topic. I had fun writing that, but today I want to start digging into the nuts and bolts of the topic.

Today, I'm going to try to explain briefly what 3D printing is, and how it works. In future weeks we'll discuss why you might (or might not) be interested in getting into 3D printing. And then we'll move on to the nitty gritty of everything you need to get started with 3D printing, including thoughts around which printer might be right for you. At then end of this post you can see some pictures of the very first proper print I ever did and in future posts we'll see further fruits of my 3D printing labours - which, spoiler alert, I'm thrilled with!

So what is 3D printing?

Before I begin, half-way down this post I have pasted a video illustrating the process that I'm about to describe. For those who prefer video-format, check it out (full credit to VogMan on Youtube) for those who prefer to read...read on!

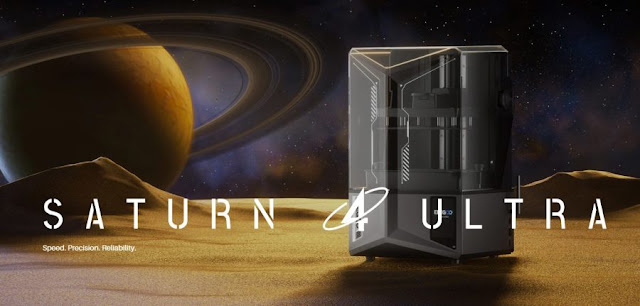

There are two main types of consumer-oriented 3D printers: resin printers and filament (PLA / FDM) printers. Filament printers (which melt a spool of plastic and squirt it - like a hot glue gun - to make 3D shapes) are great for printing terrain, but (at time of writing) they cannot offer the detail that resin printers do. From here on out I'm only going to talk about resin printing.

So I guess it's useful to start by talking about resin itself. Resin looks a lot like plastic, that's because it's a component of many plastics. The resin we'll be discussing is liquid at room temperature (it's typically the consistency of crepe batter - though resins vary in viscosity), but when it's irradiated with UV light (of a specific wave length) it cures, hardening to a material resembling hard plastic.

And now that we have a sense of what resin is, we can better understand how 3D printing works. The printer has a vat with a clear plastic film bottom which holds the liquid resin (like a glass-bottomed boat). Below the clear film bottom is a transparent LCD screen which (like any LCD screen) can create images, we'll get into the purpose of this LCD screen in a second but first, let's look beneath it. At the bottom of the 3D printer are powerful UV lights of that specific wavelength needed to cure the resin. So the UV lights shine up onto the LCD screen which creates an image of the negative of what you are printing. So the LCD screen masks off areas that you don't want the UV light to hit, but lets the light through to cure the resin in layers to build up a 3D object. It ends up creating a 3D object made out of thousands of 2D layers - very much like a CAT scan.

But how do you control the height of the layers that the lights are curing? Well, above the vat of liquid resin is a metal build plate on a strut that allows it to move up and down. So the machine moves the build plate to 20 microns above the base of the vat - immersing the build plate in the liquid resin and then the UV light cures areas of resin (through the LCD screen) onto the build plate. Then the build plate moves up by 20 microns, the LCD screen changes configuration to display the 2D area of the next layer and the process repeats itself. Thousands of times per miniature.

This 20 micron height is adjustable, it is the lowest that printers can consumer currently manage. The lower the layer height you set, the better resolution you will have on your miniature, but the longer it will take (because it will require this process to repeat itself twice as much compared if you set the layer height to 40 microns. A standard 32mm miniature (Warhammer sized) would take around 5 hours to print with this set-up.

Here's a 6 minute video that demonstrates the process:

I still remember the first real miniature that I printed, after running a bunch of calibration prints, and it really felt like some mix of science and magic.

Below you can see a play-by-play of my very first print.

Comments

Post a Comment

Tell me all...